Injector input

the voltage to the fuel injector was 5 volts, i checked this by putting a pin down the input signal wire carefully. i then used my voltmeter and recorded 14 volts to the injector.

we check the fuel injector voltage so we know that they a getting proper voltage to them and opening properly.

if the injector was getting a lower voltage than normal the engine would not be getting a proper amount of fuel and would not be running correctly because the injectors would not be opening as much as they should be.

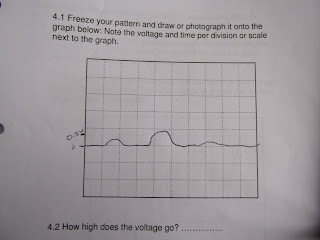

below is a circuit diagram of the injectors:

TPS input

the 5 volt input wire to this sensor was yellow.

the purpose of this wire is to provide voltage to the sensor, if the sensor was not getting a full 5 volts it would not be sending a good reading to the ecu and the engine would not be running at its peak performance.

Ground at TPS sensor

the voltage at the earth wire of this sensor was 0.002v. this is a good voltage to have because it means that there is very little resistance in the circuit and all connections are good.

If the voltage across the earth wire was high, it is likely that there would be a loose connection or some sort of resistance in the circuit.

TPS output

the voltage of the output of the sensor when the throttle is closed was 0.38v.

when i opened the throttle half was the output voltage was 2.23v.

when i opened the throttle all the was the voltage output was 3.78

I then slowly opened the throttle and made sure my voltage slowly went up without any glitches, this means that my TPS is smooth with no carbon build up.

I located the "idle switch wire" and it was around 0v when the throttle was closed, then when i opened the throttle all the way i got around 12.4 volts

I got all of these reading using my voltmeter, set to 20volts dc. i had common earth and then i put my positive probe in each of these wires.

this sensor was a switch type because it gives a reading when the throttle is closed and fully open.

some of the things that could of given the ecu a wrong output signal is:

bad earth connection

faulty input voltage

below is a drawn circuit diagram of the TPS circuit:

ECT Sensor

When i measured the supply voltage for the ECT sensor i measures 3.58v, i measured this when the engine was at normal operating temperature, this seemed like a reasonable reading according to the data sheet.

when i started the engine found that the voltage lowered to 1.1v as the engine got a little bit hotter.

At colder temperatures the ECT sensor sends a higher voltage to the ecu which tell the injectors to stay open longer to squirt more fuel into the combustion chamber so the engine can warm up faster.

the ecu could get a wrong voltage if the thermistor in the sensor was fault or there was a bad ground connection.

Ground coolant temperature sensor

When i located the ground wire, the voltage was 0.1mv, this tells that it is a good ground and the ecu will get a accurate reading from the sensor.

If the ground wire was not good, the ecu would get faulty reading and could make the engine to ritch or lean.

below is a drawn diagram of the ECT circuit:

RPM/ Crank Angle Sensor

for this test i set my multimeter to AC volts

i turned on the engine and measured the signal wire voltage and i got 90mv,

when i increased the revs to 2500 rpm i got 197mv

For this test i set my multimeter to DC volts

with the engine at idle speed i was getting a reading of 1.2v

i then increased the rpm to 2500 and got a reading of 1.6v

For this test i set my multimeter to Hertz

at idle i recorded 5kHz

i then increased the speed to 2500rpm and recorded 7.5kHz

for all of the above tests i set my multimeter to the required setting, i also had the same common ground and put my positive probe into the signal wire input.

i think that AC volts gave the best reading because i could really see the voltage go up when i changed the RPM

changing the the functions on your multimeter can help because it helps you to get a better picture of what your signal is doing.

If the ecu did not receive the correct signal from this sensor the engine would not properly because this is the most important sensor as it tells the others what the conditions are.

below is a drawn diagram of the sensor:

MAP sensor

when i found the input wire to the map sensor i was told to measure the reading using volts DC, the reading i got was 1.8v, this was with the ignition on but the engine not running.

i then started the engine and got a reading of 0.48v.

I then gave the engine a short acceleration and recorded 1.8 volts.

this shows my reading are correct because when the throttle is closed there is full vacuum because no pressure can get in so the input voltage is low and then when the throttle gets opened, there is no vacuum so the voltage gets higher.

if the ecu received the wrong signal from the MAP sensor it would tell the injectors to stay open too long or too short and could make the engine run too ritch or too lean.

IAT Sensor

For this sensor i found the input wire and measured the voltage DC with the ignition on but the engine not running. i recorded 3.3v.

this voltage is less than the ECT sensor input, this shows that the IAT sensor is hotter than the ECT sensor

the air intake temperature affects the ecu outputs for the fuel injection because it works out the temperature of the air and tells the injectors to squirt "x" amount of fuel in to atomize the fuel better.

the IAT has a thermistor inside it which lowers its resistance as it gets hotter this means there is more volt drop across the second resistor which puts out a lower voltage.

the ecu can get an incorrect reading if the sensor gets damaged or dirt caught in it.

Camshaft Position Sensor

for this task i was told to record different functions and discuss which of the function show the sensor is good.

DC volts = 19.5mv

AC volts 1.2v

Hertz = 0.09kHz

Duty cycle = 14%

I think that AC volts tells me that the sensor is working because it has a good input voltage.